Welcome to CEC, IIT Madras

The Central Electronics Centre (CEC) at the Indian Institute of Technology Madras (IITM) is a multidisciplinary technical facility dedicated to providing high-quality support in the areas of electronics servicing, calibration, testing, training, R&D, and fabrication. Established in 1971 with a modest mandate, the Centre has evolved into a comprehensive and technically sophisticated unit supporting academic, research, and industrial stakeholders within and beyond the Institute.

Since its inception, CEC has played a critical role in supporting electronic systems across departments by establishing specialized laboratories, offering regular and custom-designed training programs, and developing capabilities for complex servicing tasks. With early support from Indo-German collaborations and agencies such as GTZ, the Centre introduced full-fledged infrastructure for electronic servicing and training, and began conducting structured programs for both university faculty and technical personnel.

Over the decades, CEC has steadily expanded its scope, adding specialized capabilities in solar photovoltaic systems, thermal calibration, environmental testing, SMT fabrication, EMI/EMC testing, and advanced electronics diagnostics. It has established and maintained ISO 9001:2000 certification for servicing, testing, calibration, training, and development activities. The Centre also holds NABL accreditation for testing and calibration laboratories under ISO/IEC 17025 standards, with facilities recognized and certified by the Bureau of Indian Standards (BIS).

CEC continues to offer a wide portfolio of services—from the calibration of electro-technical and thermal instruments to SMT assembly and optical inspection, from electronics repair and R&D consultancy to field servicing of controllers and instrumentation systems. The Centre also conducts training and development programs for academic and industry partners, including tailored modules in electronics instrumentation, product evaluation, and quality standards compliance.

Functioning as a support hub and innovation enabler, CEC integrates technical rigor, operational reliability, and institutional knowledge, reinforcing IIT Madras’s mission to advance education, research, and industry collaboration in the field of electronics and instrumentation.

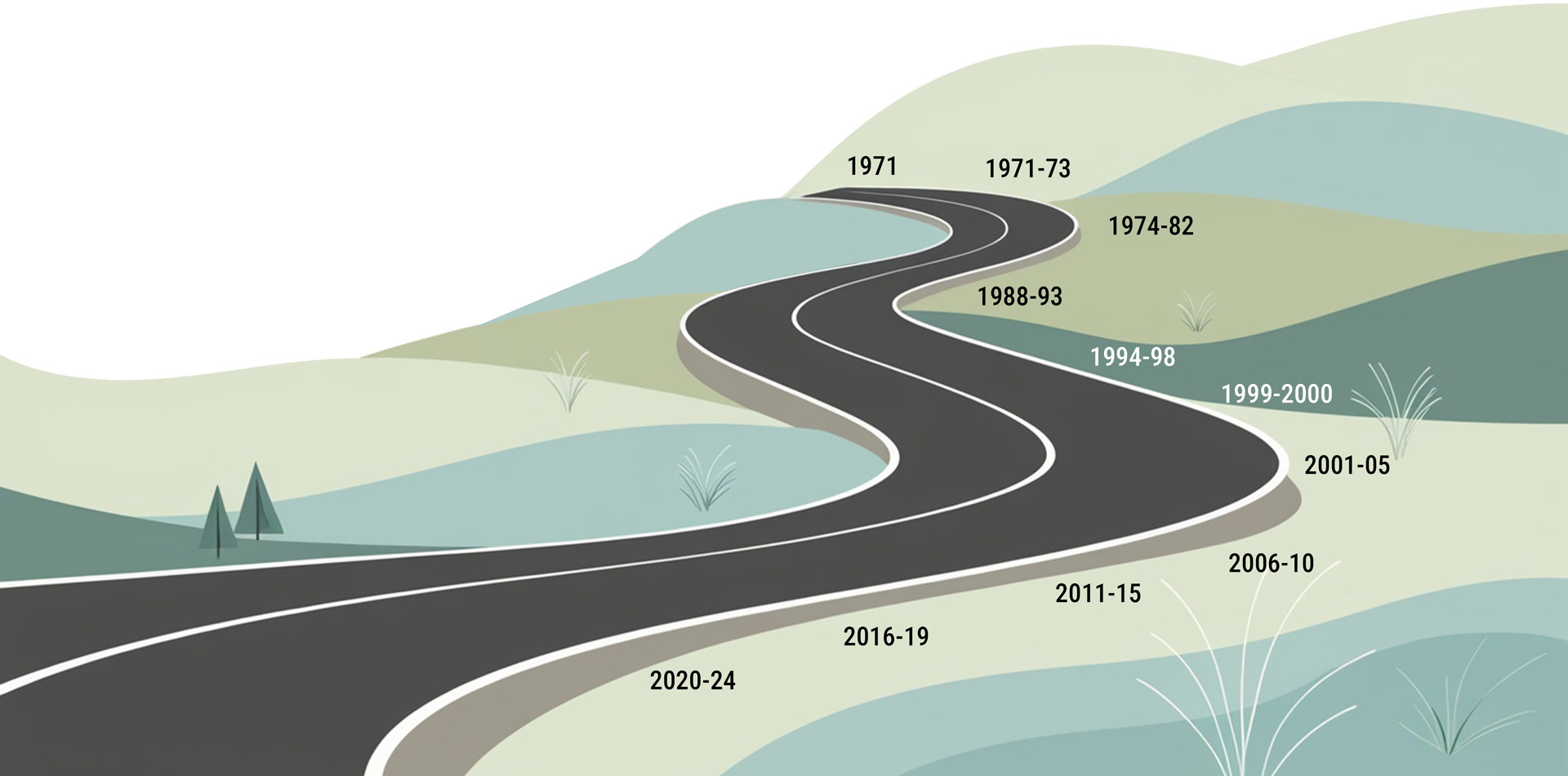

Brief Timeline of Our Journey

CEC Established

- Servicing activities initiated at a basic level.

- First 1½-year Apprentice Program launched.

Facilities Enhanced

- Infrastructure development under the Indo-German Project.

- Full-fledged laboratories for Servicing and Training established.

- First 6-week Training Program (under UGC) in Electronics Instrumentation for university staff conducted.

Servicing & Fabrication

- Focus on servicing and fabrication of setups for the measurement of mechanical parameters.

- Two Apprentice Training Programs conducted.

- Proposals submitted to further build up CEC under the Indo-German Project.

Training Programs Regularized

- New Indo-German Project commenced.

- Modern facilities established with support from GTZ, Germany.

- CEC personnel trained in Germany.

- Expansion of servicing and training activities.

- One-year CEC Training Program made a regular annual offering.

- Eight Short-Term Courses conducted for industries.

- Two-week course delivered at the University of Malaysia.

- Strengthened engagement with industry.

EMC Test Facility Established

- Complex servicing assignments undertaken.

- EMC Test Facility set up.

- MoU signed with Siemens Solar Industries (USA) to conduct SPV Training Programs.

- 7 Designers and 27 Field Technicians trained in SPV technologies.

- Additional support received from GTZ, Germany for spare procurement.

- Laboratory infrastructure further modernized.

Solar Photovoltaic Park

- MoU signed between IITM and IREDA to conduct SPV Training Programs.

- Solar Photovoltaic Park established.

- Training conducted for 3 System Technicians and 9 Field Technicians.

- MoU signed between IITM and AMET for ETO (Electro-Technical Officers) Training Programs for Merchant Navy personnel.

- Three 12-week programs conducted for ETOs.

- Additional development projects initiated.

ISO Certification & Calibration Expansion

- New facilities created for Testing and Calibration activities.

- ISO 9001:2000 Certification obtained for Servicing, Training, Testing, Calibration, and Development activities.

- NABL accreditation received for Testing and Calibration services as per IEC 17025:2005 standards.

- Development of a bicycle-pedaled lighting system for deployment in the Andaman and Nicobar Islands.

SPV and Electronics Training for Students

- Development of SPV-based LED street lighting and inverters for rural healthcare infrastructure.

- Regular practical lab sessions on Electronics introduced for first-year B.Tech students.

- SPV-powered seawater desalination demonstrator plant developed.

Thermal Calibration Laboratory Established

- Thermal Calibration Laboratory established and accredited.

- Electrical testing scope expanded, including capabilities for battery testing.

- Electronics Module for first-year B.Tech students revised and shifted to semester-end format.

NABL Accreditation and Training Expansion

- Practical electronics laboratory sessions for B.Tech students continued.

- Testing services introduced for IT products and environmental safety.

- NABL accreditation obtained for Electronic Testing Laboratory.

- BIS certification achieved for both Electrical and Electronics Testing Laboratories.

- Short-term training programs for industries conducted on specialized topics.

Scaling Excellence in Electronics Manufacturing & Health Technology

- The MacDermid Alpha Centre of Excellence in Electronics Assembly and Skills Development was inaugurated in April 2023, establishing a full SMT fabrication line at CEC.

- The facility supports hands-on training and PCB assembly, targeting the upskilling of 1,000 engineers and diploma holders annually.

- India’s first Mobile Medical Devices Calibration Facility was launched in April 2024 under the ‘Anaivarukkum IITM’ initiative.

- The mobile unit provides on-site calibration services to healthcare centres across India, ensuring accuracy and quality in medical diagnostics.

Brief Timeline of Our Journey

CEC Established

• Servicing started at minimum level

• First Apprentice Program (1 ½ years) commenced

FACILITIES ENHANCED

- Infrastructure development under the Indo-German Project.

- Full-fledged laboratories for Servicing and Training established.

- First 6-week Training Program (under UGC) in Electronics Instrumentation for university staff conducted.

SERVICING & FABRICATION

- Focus on servicing and fabrication of setups for the measurement of mechanical parameters.

- Two Apprentice Training Programs conducted.

- Proposals submitted to further build up CEC under the Indo-German Project.

Training Programs Regularized

- New Indo-German Project commenced.

- Modern facilities established with support from GTZ, Germany.

- CEC personnel trained in Germany.

- Expansion of servicing and training activities.

- One-year CEC Training Program made a regular annual offering.

- Eight Short-Term Courses conducted for industries.

- Two-week course delivered at the University of Malaysia.

- Strengthened engagement with industry.

EMC Test Facility Established

- Complex servicing assignments undertaken.

- EMC Test Facility set up.

- MoU signed with Siemens Solar Industries (USA) to conduct SPV Training Programs.

- 7 Designers and 27 Field Technicians trained in SPV technologies.

- Additional support received from GTZ, Germany for spare procurement.

- Laboratory infrastructure further modernized.

Solar Photovoltaic Park

- MoU signed between IITM and IREDA to conduct SPV Training Programs.

- Solar Photovoltaic Park established.

- Training conducted for 3 System Technicians and 9 Field Technicians.

- MoU signed between IITM and AMET for ETO (Electro-Technical Officers) Training Programs for Merchant Navy personnel.

- Three 12-week programs conducted for ETOs.

- Additional development projects initiated.

ISO Certification & Calibration Expansion

- New facilities created for Testing and Calibration activities.

- ISO 9001:2000 Certification obtained for Servicing, Training, Testing, Calibration, and Development activities.

- NABL accreditation received for Testing and Calibration services as per IEC 17025:2005 standards.

- Development of a bicycle-pedaled lighting system for deployment in the Andaman and Nicobar Islands.

SPV & Electronics Training for Students

- Development of SPV-based LED street lighting and inverters for rural healthcare infrastructure.

- Regular practical lab sessions on Electronics introduced for first-year B.Tech students.

- SPV-powered seawater desalination demonstrator plant developed.

Thermal Calibration Laboratory Established

- Thermal Calibration Laboratory established and accredited.

- Electrical testing scope expanded, including capabilities for battery testing.

- Electronics Module for first-year B.Tech students revised and shifted to semester-end format.

NABL Accreditation & Training Expansion

- Practical electronics laboratory sessions for B.Tech students continued.

- Testing services introduced for IT products and environmental safety.

- NABL accreditation obtained for Electronic Testing Laboratory.

- BIS certification achieved for both Electrical and Electronics Testing Laboratories.

- Short-term training programs for industries conducted on specialized topics.

Scaling Excellence in Electronics Manufacturing & Health Technology

- The MacDermid Alpha Centre of Excellence in Electronics Assembly and Skills Development was inaugurated in April 2023, establishing a full SMT fabrication line at CEC.

- The facility supports hands-on training and PCB assembly, targeting the upskilling of 1,000 engineers and diploma holders annually.

- India’s first Mobile Medical Devices Calibration Facility was launched in April 2024 under the ‘Anaivarukkum IITM’ initiative.

- The mobile unit provides on-site calibration services to healthcare centres across India, ensuring accuracy and quality in medical diagnostics.